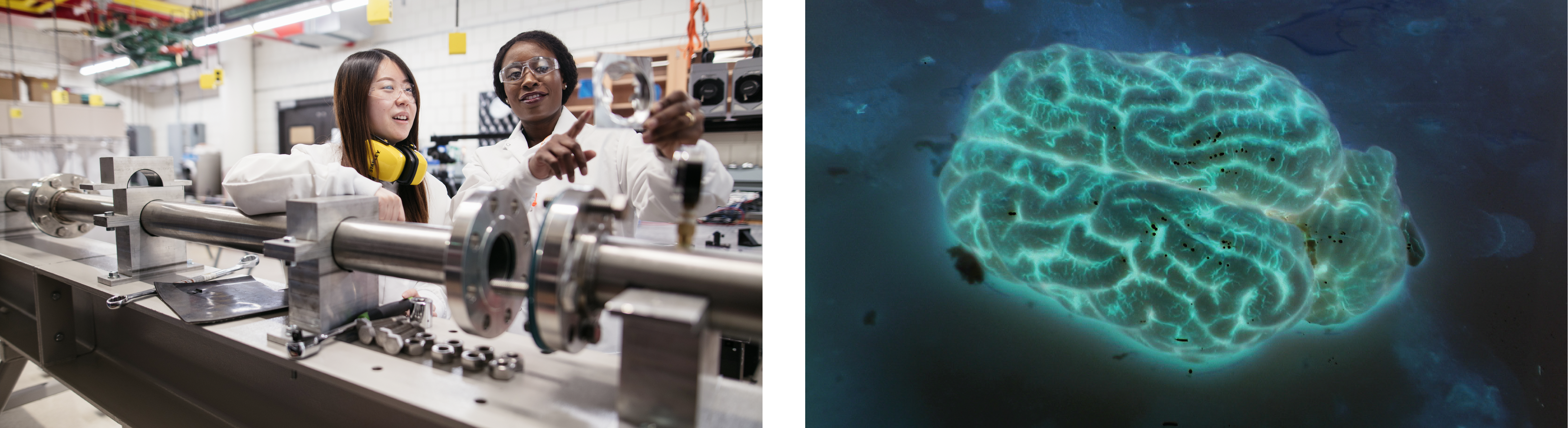

Sarah Bentil, assistant professor of mechanical engineering, leads a research team that is illuminating the invisible: non-penetrative brain injuries suffered by those returning from combat due to shock waves.

Brain as a material

Bentil’s expertise is characterizing how soft materials deform in response to force or impact, including shock waves, and predicting the material’s behavior using a mathematical model. Her research uses an approach that focuses on the brain as a material. Over time, her team’s work will evolve to shed light on how shock waves cause invisible brain injuries that cannot be detected from MRI scans.

Researchers in Bentil’s line of work often use shock tubes to mimic blasts, but not all of them are created equally.

Enter the oxyacetylene-driven shock tube – a device that Bentil’s group designed and fabricated for experiments investigating traumatic brain injury mechanisms caused by the propagating shock wave. Unlike conventional compression-driven shock tubes, which cannot fully mimic the pressure versus time profile of a shock wave, an oxyacetylene-driven shock tube can accurately generate the type of shock waves created when an explosive device is detonated.

The 3-inch diameter shock tube is comprised of a 1-foot driver section filled with oxygen and acetylene, which is connected to a 15-foot long driven section with an end that is open to the atmosphere. The driver and driven sections are separated by a diaphragm. By igniting the oxygen and acetylene in the driver section, the diaphragm ruptures and creates the shock wave.

“We have conducted shock wave experiments with brain tissue and are able to understand how the brain surface changes its shape due to the propagating wave,” said Bentil.

Accessible, new instrument

The oxyacetylene-driven shock tube more accurately replicates a blast wave, is just as cost effective as compression-driven shock tubes, and is not as expensive and dangerous to operate as blast-driven shock tubes. Bentil’s oxyacetylene-driven shock tube is a new, pragmatic option that makes blast-induced traumatic brain injury research more accessible to researchers because it does not require detonating an explosive.

“The oxyacetylene-driven shock tube is built from commercially-available parts. So if a component of the shock tube needs to be replaced, I can go to the local hardware store and easily buy what I need to replace it,” Bentil said.

Bentil says that Iowa State University is one of the first academic institutions to use an oxyacetylene-driven shock tube for blast impact research.

Meeting in the middle

Bentil aims to quickly and widely share experimental data from the shock tube experiments with others in the brain injury research community. With increased understanding of the brain’s response to shock waves, Bentil hopes that improved personal protective gear can be designed to prevent or mitigate blast injuries.

“Most people work on addressing questions related to traumatic brain injuries from the outside-in, such as how to design new helmet liners to mitigate the effects of the shock wave. However, how the brain is actually responding to the shock wave remains unknown,” Bentil said. “We’re working on the problem from the inside-out – and it is my hope that the entire brain injury research community will merge in the middle.”

Bentil’s project is supported by the Roy J. Carver Charitable Trust of Muscatine, Iowa.