Unique qualities promise strength

The applications for 3-D concrete printing are expansive, ranging from residential housing and bridges to architecture and aesthetic structures. In events where structural integrity of a building or bridge has been compromised, 3-D concrete printing may be a strong solution to building in challenging situations, even with the required cure time.

“Unlike polymers and metals, concrete needs sufficient time to solidify and to be capable of holding the weight of the layers deposited above,” Wang said.

Though the amount of time required for concrete to solidify exceeds other 3-D printing materials, its qualities in strength and detail surpass those of metals and polymers.

Formulating the perfect recipe

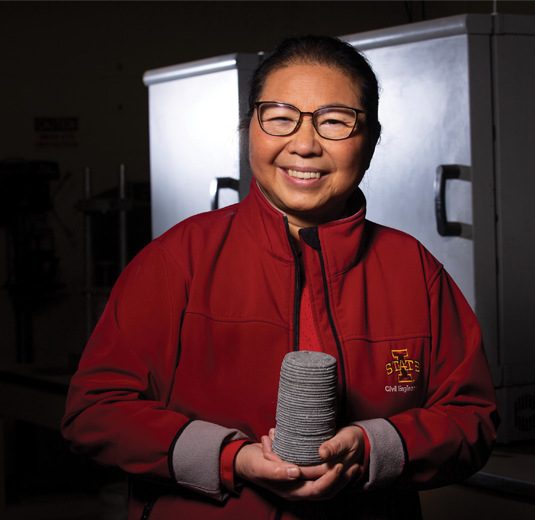

As 3-D concrete printing gains popularity, the central challenge of Wang’s research is ensuring concrete flow is optimal while retaining an unmalleable shape during the hardening phase.

“If the stiffness or strength of the printed concrete does not develop promptly, the printed objects may slump, distort or collapse with time,” Wang said.

So, Wang and her research team are applying rheological concepts to optimize concrete flows and shape stability.

To improve cement flows for printing, a variety of chemical agents are used to adjust the rheological behavior of the material. The recipe for success in formulating the perfect concrete mixture is balancing flow ability with solidification time. Dispersants and thixotropic agents function to expedite the flowability while preventing separation of materials in the mixture and enhancing shape stability of the printed products.

Wang and her team also assess the resulting quality of the printed material. Using different printing speeds and cement mixtures,

The level of detail that is provided by concrete along with competitive quality makes the material and technology advantageous. Wang hopes that 3-D printing techniques can provide comparable quality and texture to other 3-D printed materials.

“The time-dependent qualities of concrete demand breakthroughs in concrete mix proportioning, processing, and rapidly and effectively evaluating methods for the quality assurance of the printed products,” Wang said.